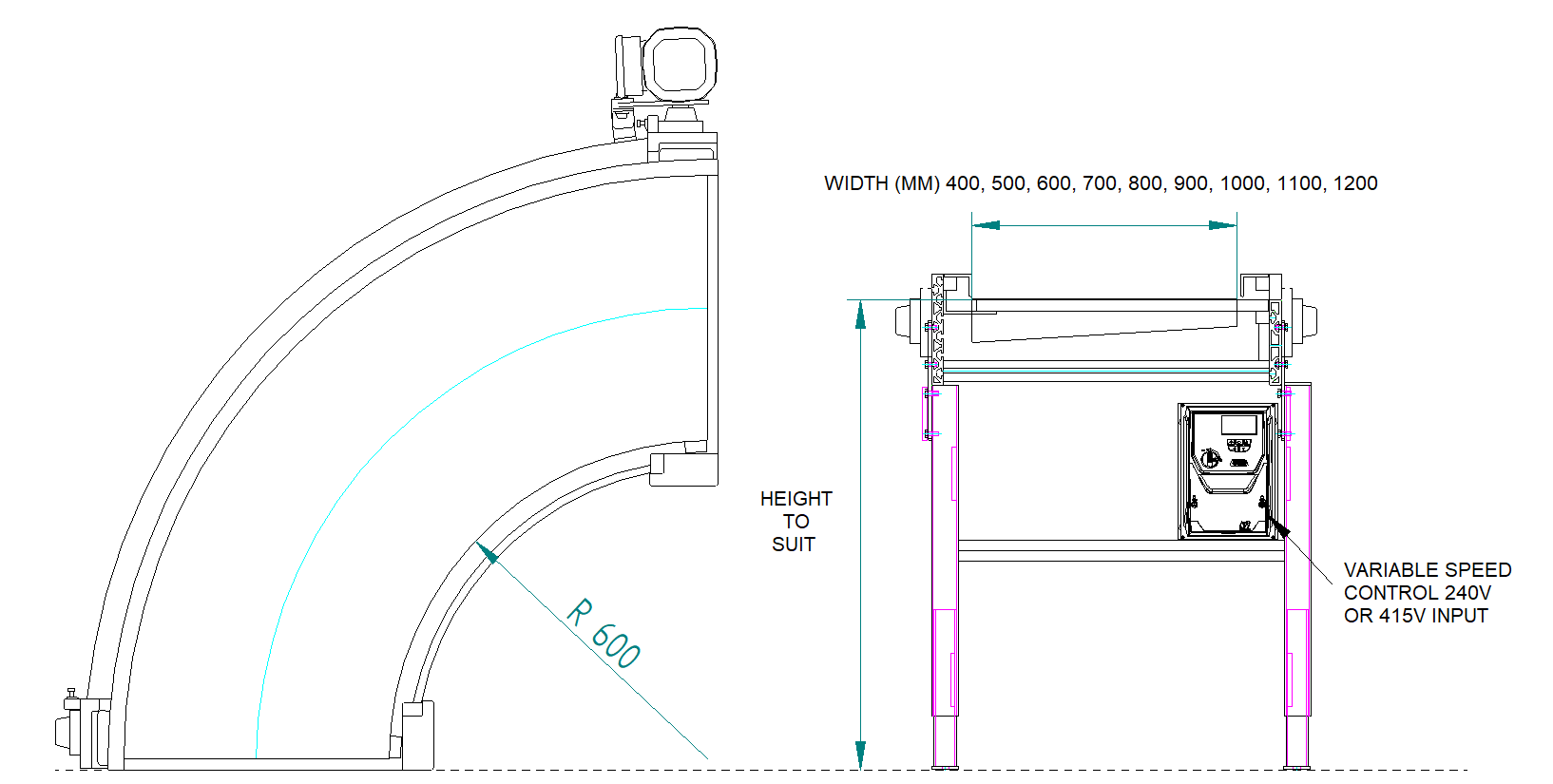

Curved Belt Conveyor

A curved belt conveyor is a specialized type of conveyor system designed to navigate around corners or curves while transporting goods along a continuous path. This conveyor utilizes a flexible belt that can bend and flex to follow the curvature of the conveyor track, allowing for smooth and efficient transportation of items around obstacles or through confined spaces. Curved belt conveyors are commonly used in industries such as manufacturing, distribution, and logistics, where space constraints or layout considerations necessitate the use of curved conveyor sections to optimize workflow and material flow. These conveyors can be customized to accommodate various curve angles and radii, ensuring precise and reliable handling of goods while maximizing operational efficiency.

Key Features of Curved Belt Conveyors:

o Flexibility: Curved belt conveyors offer flexibility in material handling by allowing for changes in direction without the need for additional transfer points or manual handling.

o Space-saving Design: The curved configuration of the conveyor helps optimize floor space by efficiently maneuvering around obstacles and fitting into tight layouts.

o Continuous Material Flow: The smooth transition around curves ensures uninterrupted material flow, minimizing product damage and improving overall efficiency.

o Variable Curve Angles: Curved belt conveyors can be customized to accommodate various curve angles, allowing for versatility in layout design and adaptation to specific operational requirements.

o High Capacity: Despite their curved design, these conveyors maintain high throughput capacities, making them suitable for handling a wide range of materials and applications.

o Easy Integration: Curved belt conveyors can be seamlessly integrated into existing conveyor systems or used as standalone units, offering flexibility in system configuration and expansion.

o Durability and Reliability: Constructed from high-quality materials and featuring robust construction, curved belt conveyors are built to withstand heavy-duty use and provide long-lasting performance.

o Low Maintenance: With minimal moving parts and straightforward maintenance requirements, curved belt conveyors offer cost-effective operation and reduced downtime.

Applications of Curved Belt Conveyors:

Curved belt conveyors find applications across various industries, including:

o Manufacturing: Transporting materials around production lines and assembly processes.

o Distribution and Warehousing: Optimizing material flow in distribution centers and warehouses.

o Food Processing: Handling food products in processing and packaging facilities.

o Automotive: Conveying components and parts in automotive manufacturing plants.

o Logistics and E-commerce: Sorting and distributing parcels and packages in logistics hubs and fulfillment centers.

o Airport Baggage Handling: Routing luggage and baggage around airport terminals and baggage handling systems.

Curved Belt Conveyors offer a versatile and efficient solution for navigating bends and curves in material handling applications, ensuring smooth and continuous transportation of goods while maximizing space utilization and operational efficiency.

| Technical Parameters | ||

| Conveyor angle | 45°/90°/180° | |

| Conveyor inner radius | 400 to 1400 mm | others on request |

| Drive location | underneath | |

| Drive and speed | up to 15 m/min | others on request |

| Standard distributed load | up to 30 kg/m | others on request |

| Belt thinkness | 3.0mm | others on request |

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training