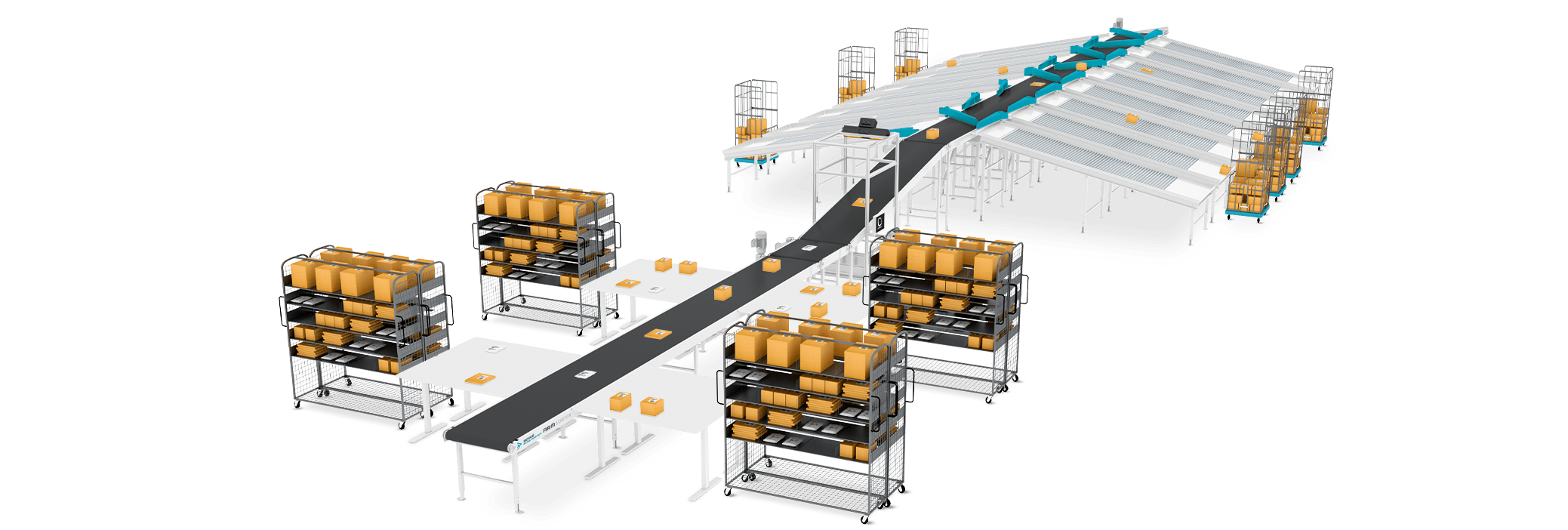

Swing Arm Sorter

Swing Arm Sorters are a type of high-speed sorting system commonly used in distribution centers, warehouses, and logistics facilities. These automated sorting systems are designed to efficiently sort a wide variety of items based on predetermined criteria such as destination, order, or customer.

Key Features:

Swing Arm Design: Swing Arm Sorters feature swinging arms that extend from the main conveyor line to divert items onto designated chutes, bins, or conveyor lines. These arms move rapidly and accurately to sort items at high speeds.

Sorting Accuracy: Swing Arm Sorters offer high sorting accuracy, ensuring that each item is correctly directed to its intended destination. This accuracy is crucial for efficient order fulfillment and logistics operations.

High Throughput: Swing Arm Sorters are capable of handling large volumes of items with high throughput rates. This makes them ideal for distribution centers and warehouses with demanding sorting requirements.

Versatility: These sorting systems can handle a wide range of items, including parcels, packages, boxes, and more. They can be customized to accommodate different sizes, shapes, and weights of items.

Integration with Automation: Swing Arm Sorters can be seamlessly integrated with other automation technologies such as barcode scanners, conveyor systems, and warehouse management systems (WMS) to create fully automated sorting processes.

Minimal Downtime: With robust construction and reliable operation, Swing Arm Sorters require minimal downtime for maintenance and repairs, ensuring continuous operation and productivity.

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training