Flat Belt Conveyor

Key Features of Soyer Belt Conveyors:

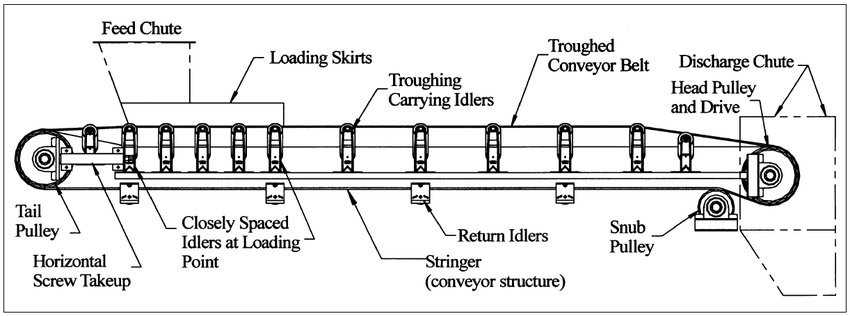

· Conveyor Belt: The conveyor belt is the primary component of the system, consisting of a continuous loop of material that rotates around two or more pulleys. The belt is typically made from rubber, fabric, or plastic materials and is reinforced with layers of fabric or steel cords for strength and durability.

· Drive System: The drive system powers the conveyor belt and controls its movement. This may include electric motors, gearboxes, and pulleys to provide the necessary torque and speed for efficient operation.

· Idlers and Rollers: Idlers and rollers support the conveyor belt and help maintain its alignment and tension. These components are strategically positioned along the conveyor route to minimize friction and ensure smooth belt movement.

· Loading and Discharge Points: Loading and discharge points are where materials are loaded onto and unloaded from the conveyor belt. These points may include chutes, hoppers, or transfer points equipped with sensors or gates to control the flow of materials.

· Safety Features: Belt conveyors are equipped with various safety features to protect operators and prevent accidents. These may include emergency stop switches, guards, and safety interlock systems to ensure safe operation.

· Adjustable Speed and Tension: Belt conveyors often feature adjustable speed and tension controls, allowing operators to optimize conveyor performance and accommodate different types of materials and operating conditions.

· Modular Design: Many belt conveyors feature a modular design, allowing for easy customization and expansion to suit specific application requirements. Modular components such as conveyor sections, drives, and accessories can be easily added or removed as needed.

· Low Maintenance: Belt conveyors are known for their low maintenance requirements, with simple design and few moving parts. Regular inspection and lubrication of components are typically all that is needed to keep the conveyor running smoothly.

Applications of Belt Conveyors:

Belt conveyors are used in a wide range of industries and applications, including:

· Mining and Quarrying: Transporting bulk materials such as coal, ore, and aggregates.

· Manufacturing: Moving raw materials, parts, and finished products along production lines.

· Logistics and Distribution: Sorting and distributing packages, parcels, and pallets in warehouses and distribution centers.

· Agriculture: Handling crops, grains, and livestock feed in agricultural operations.

· Food Processing: Conveying food products such as grains, fruits, and vegetables during processing and packaging.

· Construction: Transporting construction materials such as sand, gravel, and concrete on job sites.

Overall, belt conveyors play a critical role in material handling operations, offering efficient, reliable, and versatile transportation solutions for a wide range of industries and applications.

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training