Spiral Accumulation Conveyor

Spiral Accumulation Conveyor typically consist of a spiral-shaped belt or chain that moves products along a helical path. As items travel along the spiral path, they accumulate in designated accumulation zones, where they can be held temporarily until downstream processes are ready to receive them. Spiral accumulation conveyors are commonly used in sorting and distribution centers, manufacturing facilities, and other industrial settings where buffering or accumulation of materials is required.

Key features and benefits of spiral accumulation conveyors include:

Buffering Capacity: Spiral accumulation conveyors provide ample buffering capacity to accommodate fluctuations in production or processing rates. This helps to smooth out the flow of materials and prevents congestion or jams in the conveyor system.

Space Efficiency: By utilizing a spiral configuration, these conveyors make efficient use of vertical space, allowing for compact installation in facilities with limited floor space. This vertical design also enables the conveyor to span multiple levels or floors within a facility.

Gentle Product Handling: Spiral accumulation conveyors are designed to handle a wide range of products, including fragile or delicate items, with care. The spiral path provides a gentle and controlled transport mechanism, minimizing the risk of product damage during accumulation.

Versatility: These conveyors can be customized to meet specific application requirements, including accumulation zone length, conveyor speed, and integration with other conveyor systems. This flexibility makes them suitable for a variety of material handling applications across different industries.

Increased Throughput: By preventing bottlenecks and interruptions in the production or distribution process, spiral accumulation conveyors help to maximize throughput and overall system efficiency. They ensure a continuous flow of materials, leading to improved productivity and operational performance.

Specification:

The standard slat chain width is 135 mm. Track width and the number of tracks can be customized.

Outer diameter is related to the number of slat chains. 3 lanes of slat chain are the standard design.

Inclination changes with height and number of layers, please contact us for more information.

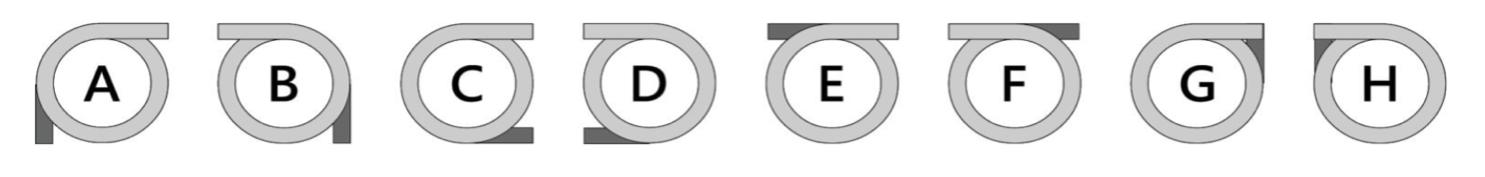

Inlet/outlet configurations.

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training