Continuous Vertical Conveyor

Continuous Vertical Conveyors offer a reliable and efficient solution for vertical transportation needs within industrial and commercial settings. By seamlessly moving materials or products between different levels, they help streamline material handling processes, improve workflow efficiency, and optimize space utilization within facilities.

Soyer Spiral Technologies:

Manufacturing Materials: Our spiral conveyors are crafted from powder-coated carbon steel, stainless steel, and feature an aluminum pillar construction.

Chain Design: Utilizing anti-slippery high-strength special spiral chains, customized effective width, with four bearings at the bottom. The chains are made of POM material and are distinguishable by their upper blue color.

Spiral Conveying Width: Available in widths of 200mm, 300mm, 400mm, and 600mm, with customization options up to 1200mm to suit specific needs.

Vertical Spiral Application: Our spiral conveyors find applications in various industries including beverage, beer, cigarette, postal, newspaper, printing, food, pharmaceutical, logistics, electronics, and more.

Conveyor Lifting Capacity (Single Motor): For carbon steel bottom chain, the maximum load is <750kg, and for stainless steel, it is <600kg.

Key features of Continuous Vertical Conveyors include:

Vertical Transport: Continuous Vertical Conveyors are capable of lifting or lowering materials or products between different floors or levels within a facility. They provide a seamless vertical transportation solution, eliminating the need for multiple conveyors or manual handling of goods.

Continuous Operation: As the name suggests, Continuous Vertical Conveyors are designed for continuous operation, allowing for a steady flow of materials or products between levels without interruption. This continuous operation contributes to increased efficiency and productivity in material handling processes.

Space Optimization: Continuous Vertical Conveyors help optimize space utilization within a facility by efficiently moving materials or products vertically, thereby minimizing the footprint required for material handling equipment. This is particularly beneficial in facilities with limited floor space or height restrictions.

Versatility: Continuous Vertical Conveyors can be customized to accommodate various types of materials, product sizes, and weight capacities. They are suitable for a wide range of applications across industries such as manufacturing, distribution, warehousing, and logistics.

Safety Features: Continuous Vertical Conveyors are equipped with safety features such as guarding, interlocks, and emergency stop buttons to ensure safe operation and prevent accidents or injuries during transportation.

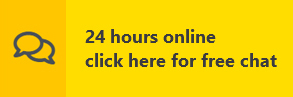

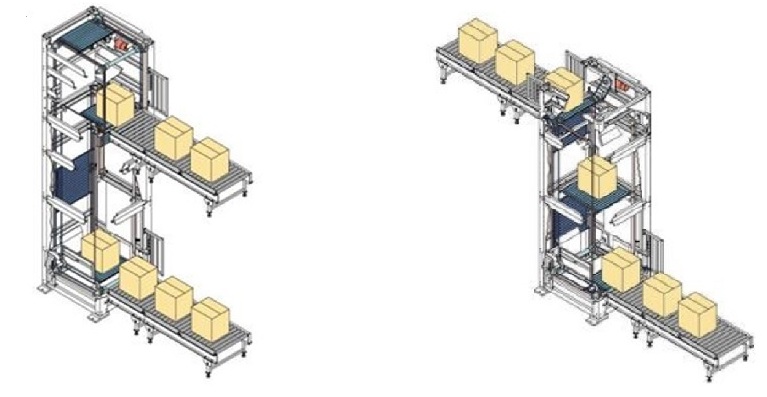

Continuous Vertical Conveyor comes in various configurations, including Z, C, E, and F, determined by the inlet and outlet orientations. Utilizing a roller shutter mechanism, it enables uninterrupted vertical material transport, ensuring optimal efficiency without disrupting workflow.

Designed for versatile material transportation, the Continuous Vertical Conveyor accommodates goods of varying sizes without strict limitations. While primarily operating in a one-way mode, it can support two-way operation as needed.

Integration with import and export conveying equipment enables seamless automation, eliminating manual operation uncertainties. Its compact structure and small footprint make efficient use of floor space.

Continuous Vertical Conveyor boasts low operational costs, reducing transmission expenses while prioritizing safety, reliability, and ease of maintenance.

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training