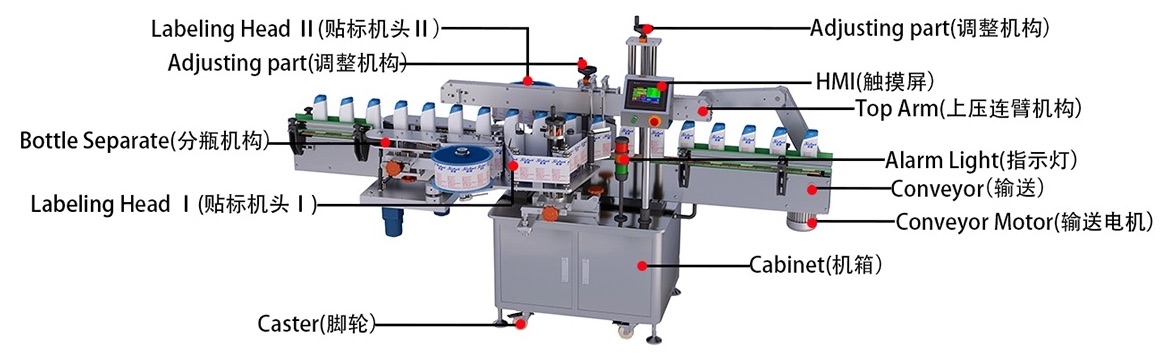

Double Side Labeling Machine

The SOYER Double Sided Labeling Machine is meticulously crafted with a user-friendly DIY design. By streamlining the machinery and opting for a modular assembly approach, it ensures simplicity and ease of maintenance. With no need for specialized professionals, maintenance and servicing tasks can be effortlessly completed. Additionally, product replacement is made seamless with straightforward adjustments, enabling quick integration back into production lines.

The entire machine is constructed from S304 stainless steel and high-grade aluminum alloy, treated with anodizing for durability and corrosion resistance.

The labeling head is powered by a cutting-edge stepper motor sourced from Japan, ensuring precise and reliable operation.

All electric eyes used are of Japanese or German origin, representing advanced photoelectric technology for accurate label detection and positioning.

Controlled by a PLC (Programmable Logic Controller) with a large-scale human-machine interface, the system boasts 60 memory units for versatile and customizable operation.

Technical Specifications:

Labeling Speed: 60-350 pcs/min (Depending on label length and bottle thickness)

Height of Object: 30-350mm

Thickness of Object: 20-120mm

Height of Label: 15-140mm

Length of Label: 25-300mm

Label Roller Inside Diameter: 76mm

Label Roller Outside Diameter: 420mm

Accuracy of Labeling: ±1mm

Power Supply: 220V 50/60HZ 3.5KW Single-phase

Gas Consumption of Printer: 5Kg/cm^2

Size of Labeling Machine: 2800(L)×1650(W)×1500(H)mm

Weight of Labeling Machine: 450Kg

Key Features of the SOYER Double Side Labeling Machine:

Multi-functionality: Suitable for labeling flat, oval, square, and round bottles.

Precise labeling: Controlled by servo motor drive to ensure perfect label placement.

Easy adjustment: Customers can easily adjust the machine for different bottle sizes without the need for part changes.

High-speed operation: Capable of labeling up to 100 bottles per minute.

Warranty: Backed by a 1-year warranty for peace of mind.

User-friendly interface: PLC and touch screen control allow for easy operation and monitoring.

Warning systems: Equipped with warning devices for insufficient labels, broken labels, no bottle detection, and more.

Versatility: Can be connected to a production line via a conveying belt for seamless integration.

The SOYER Double Side Labeling Machine is utilized across various industries for labeling cylindrical products such as bottles, jars, and containers. Its versatile design and customizable settings make it suitable for a wide range of applications, including:

Food and Beverage: Labeling bottles of sauces, condiments, beverages, and other packaged food products.

Pharmaceuticals: Applying labels to medication bottles, vials, and other pharmaceutical packaging.

Cosmetics: Labeling containers of skincare products, cosmetics, and personal care items.

Household Products: Applying labels to cleaning solutions, detergents, and household chemicals.

Chemicals and Lubricants: Labeling containers of industrial chemicals, lubricants, and automotive fluids.

Health and Wellness: Applying labels to bottles of vitamins, supplements, and health products.

Agriculture: Labeling bottles and containers of agricultural chemicals, fertilizers, and pesticides.

Automotive: Applying labels to containers of automotive fluids, oils, and lubricants.

Beverage Industry: Labeling bottles of alcoholic and non-alcoholic beverages, including beer, wine, and spirits.

Packaging and Contract Manufacturing: Providing labeling services for contract manufacturing and packaging companies serving various industries.

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training