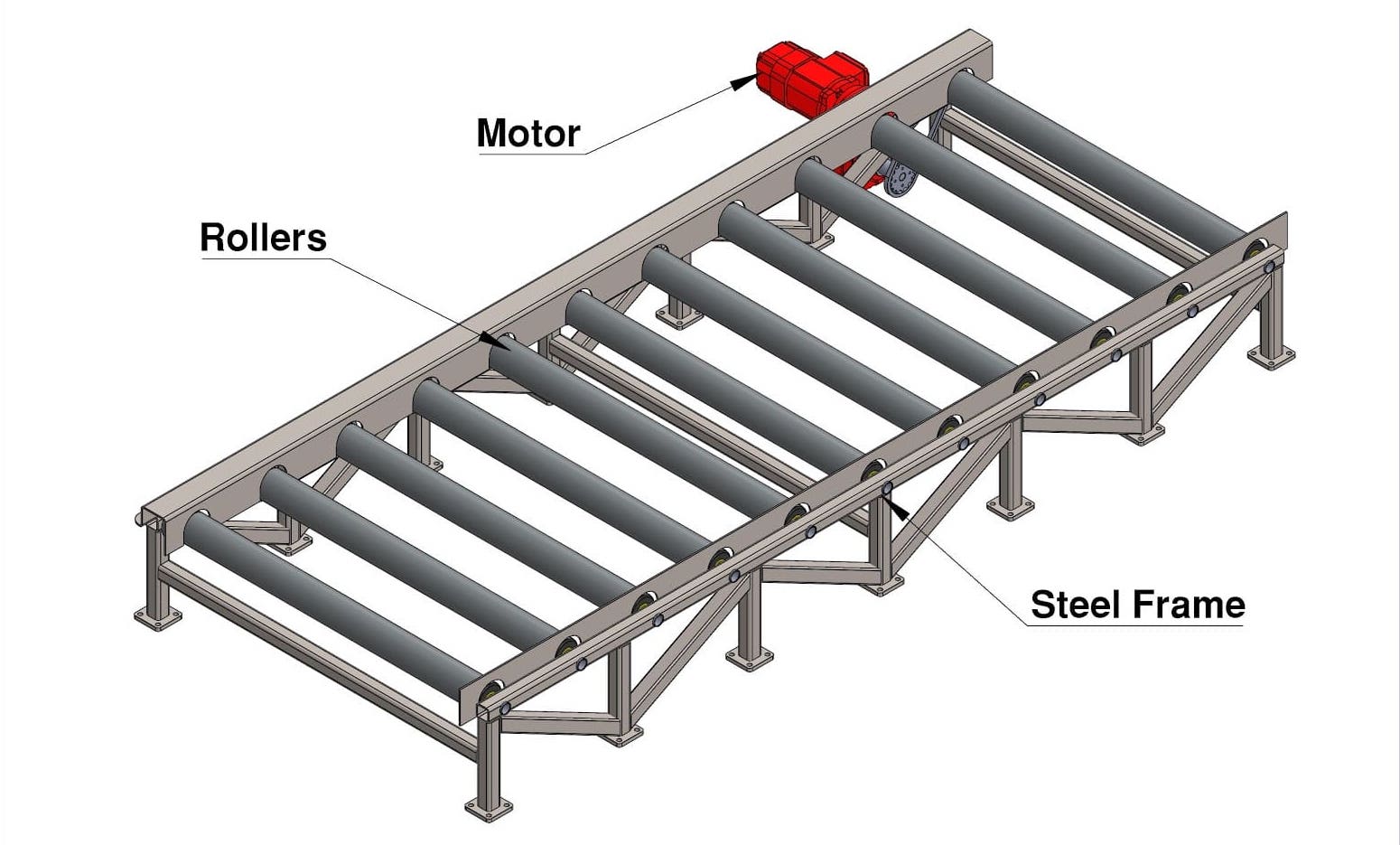

Powered Roller Conveyor

The Powered Roller Conveyor is a dynamic solution for transporting various types of products in manufacturing, distribution, and warehousing environments. Unlike gravity roller conveyors, which rely on the force of gravity for movement, powered roller conveyors utilize motorized rollers to drive product flow along the conveyor line.

Key Features:

· Motorized Rollers: Equipped with motorized rollers along the conveyor length, providing the driving force to propel products forward along the conveyor path.

· Variable Speed Controls: Adjustable speed settings allow operators to control the speed of the conveyor, accommodating different product sizes, weights, and throughput requirements.

· Accumulation Zones: Powered roller conveyors can be divided into accumulation zones, allowing products to accumulate and queue without causing congestion or disruption to the conveyor flow.

· Zero Pressure Accumulation: Advanced control systems enable zero pressure accumulation, ensuring that products are safely spaced apart to prevent collisions and product damage.

· Versatility: Suitable for transporting a wide range of products, including boxes, cartons, totes, and containers, making it ideal for use in various industries and applications.

· Modular Design: Modular construction allows for easy customization and expansion of the conveyor system to meet specific layout requirements and operational needs.

· Conveyor Merging and Diverging: Powered roller conveyors can be configured to merge or diverge product flow, facilitating efficient routing and distribution of products to different destinations.

· Integration with Automation Systems: Compatible with automation systems, such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition), enabling seamless integration with other equipment and systems.

Applications:

· Manufacturing: Transporting components, parts, and assemblies along assembly lines or production processes.

· Distribution and Warehousing: Sorting and routing packages, parcels, and pallets in distribution centers and warehouses.

· E-commerce Fulfillment: Handling and processing orders for online retail and e-commerce fulfillment operations.

· Food and Beverage: Conveying packaged food products, beverage containers, and packaging materials in food processing and packaging facilities.

· Airport Baggage Handling: Moving luggage and baggage between check-in, sorting, and loading areas in airport terminals.

· Automotive: Transporting automotive components, parts, and assemblies in automotive manufacturing plants.

The benefits of Powered Roller Conveyor include:

· Efficient product transportation.

· Increased productivity.

· Versatility in handling various products.

· Customizable to specific needs.

· Reduction in labor costs.

· Improved workflow and efficiency.

· Enhanced safety.

· Integration with automation systems.

· Zero pressure accumulation for product safety.

· Long-term cost savings..

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training