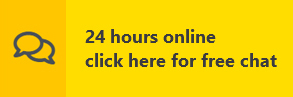

Gravity Roller Conveyor

Soyer Gravity Roller Conveyor is a simple and cost-effective material handling solution that relies on gravity to move products along a series of rollers. This type of conveyor is widely used in warehouses, distribution centers, and manufacturing facilities for transporting items with minimal manual effort.

Features of Gravity Roller Conveyor:

Simple Design: Gravity roller conveyors have a straightforward design consisting of rollers mounted on a frame, requiring minimal maintenance.

Cost-Effective: As they operate without motors or power sources, gravity roller conveyors are economical to operate and maintain.

Versatility: Suitable for various load sizes and shapes, gravity roller conveyors offer flexibility in material handling applications.

Gravity-Powered: Items move along the conveyor by the force of gravity, eliminating the need for external power sources.

Quiet Operation: With no motors, gravity roller conveyors operate quietly, creating a conducive work environment.

Easy Installation: They are easy to install and can be integrated into existing conveyor systems or used as standalone units.

Low Maintenance: With fewer moving parts, gravity roller conveyors require minimal maintenance, reducing downtime and costs.

Adjustable: Roller spacing and conveyor height can often be adjusted to accommodate different load sizes and requirements.

Technical Specifications:

Frame details: Lengths 1500, 3000 mm and curves 45° 90°

Frame widths: 300, 450 and 600 mm (overall width)

Roller lengths: 230, 390 and 540 mm (overbearing dimension)

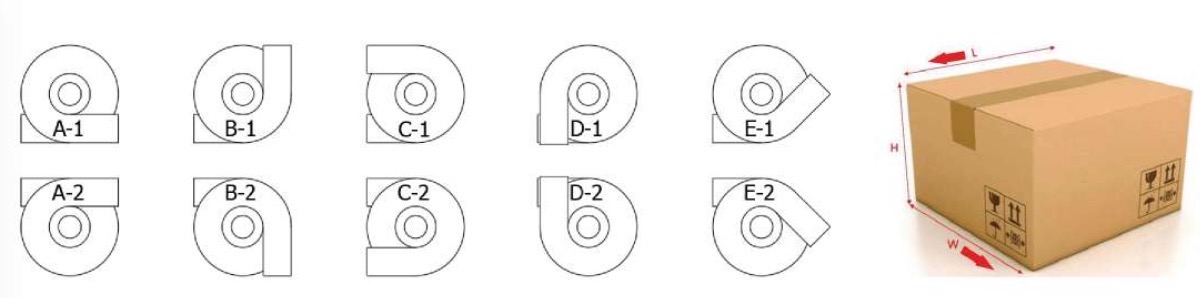

Rollers per 1500 mm frame:

75 mm pitch = QTY 20

115 mm pitch = QTY 13

150 mm pitch = QTY 10

Rollers per 3000 mm frame:

75 mm pitch = QTY 40

115 mm pitch = QTY 26

150 mm pitch = QTY 20

Stands are height adjustable from 715 – 1015 mm

Our Service includes

- · Site survey

- · 24Hours online chat

- · Project management

- · Fabrication

- · 48 Hours continuous running and testing

- · Installation and commissioning

- · Post-installation support

- · Documentation and training